QED Consulting Engineers – Melbourne-based Civil and Structural Specialist Consultancy

Light Gauge Steel Design and detailing

Light-Gauge

Steel (LGS)

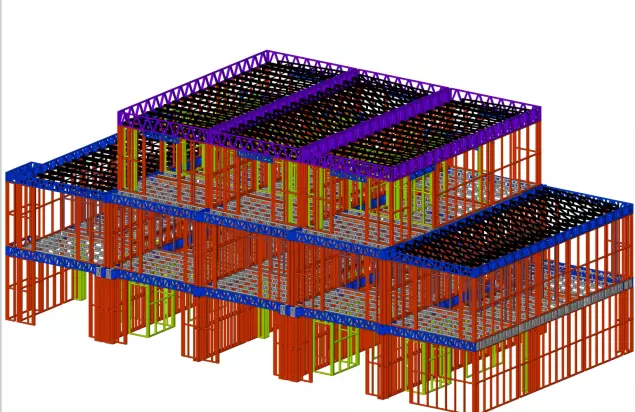

Light-gauge steel (LGS) is becoming a

more popular choice among clients, developers, Architects, and builders when

compared to traditional timber framing. QED Consulting Engineers design and

certify LGS models and shop drawings for projects of all sizes, including both

Residential and Commercial applications such as detached dwellings, townhouses,

childcare centers, Commercial fit-outs, and many more.

We are a one-stop shop for light-gauge steel projects. By choosing QED Consulting Engineers, you get a fully packaged Structural Engineering service, including light-gauge steel and hot-rolled steel designed and certified in one place. Our Engineering and LGS package is a great option for the client, reducing overall design development duration and consequent construction costs. The complete LGS and Engineering package service is highly recommended for a hassle-free, smooth, and successful operation, providing a complete in-house service from design development through to construction.

In the residential sector, Light-gauge steel is as common as traditional timber framing due to its many advantages. Many steel fabricators are including LGS in their range of supplies and services due to its popularity, especially in the Commercial sector as it is now the industry standard.

Firstly, aside from the obvious benefits of LGS framing being termite and rot-resistant, with a higher fire-rating, and corrosion resistance, light-gauge steel is more sustainable as it is 100% recyclable.

Secondly, since Commercial native

logging and timber harvestry is no longer permitted in select locations around

Australia as of January 2024, the price of timber has severely increased.

Clients, Architects, and Builders are increasingly opting for LGS stud framing

since it is competitively priced as a more affordable option than timber. In

addition the inexpensive material cost, the construction costs involved with

light-gauge steel are significantly less. This is because the panels are

prefabricated and installed on-site. This results in a shorter build duration

and subsequently cheaper overall construction cost.

Lastly, the availability of skilled

steel framers to assemble and install light-gauge steel panels is no longer an

issue, due to the popularity of the material in the Construction industry.

Are you ready to elevate your project with the strength and flexibility of light-gauge steel? Contact QED Consulting Engineers today to learn more about our structural engineering services. Let us help you build strong, sustainable, and innovative structures with confidence.

advantages of Light gauge steel framing:

-

Lightweight - Light Gauge Steel framing has numerous benefits over timber throughout the entire construction process. Firstly, lightweight steel framing panels are much lighter than their timber counterparts. This makes them extremely easy to transport and handle on-site. Consequently, this reduces on-site labour costs without requiring heavy-duty cranes and machinery. The price of a LGS frame is very comparable with timber when considering reduced construction time and labour costs.

Durability - when it comes to durability, LGS stands out as top choice. compared to soft wood timber, light gauge steel offers superior resistance to natural disaster and demands minimal ongoing maintenance . LGS innate resilience make it naturally resistant to termites, eliminating the need for chemical treatments . the advantage is especially significant in Australia, where termite-related risks pose a greater threat to home structural integrity .

-

Fast and Accurate - cold-formed steel sections are consistently cut with low tolerances due to precise CNC milling. Overall, this enables much quicker construction time compared to traditional timber construction.